3D Printing for Production

3D printing or additive manufacturing enables you to produce geometrically complex objects, shapes and textures. It often uses less material than traditional manufacturing methods and allows the production of items that were simply not possible to produce economically with traditional manufacturing.

01

Key Features of Multi-Engineering Prototype Manufacturing:

If you’re new to 3D printing technology, it might be helpful to compare it to traditional methods of manufacturing.

The two principal traditional methods of manufacturing are:

-

Subtractive Manufacturing (SM) is the controlled removal of material, like milling, for example.

-

Formative Manufacturing (FM) takes a material, usually a plastic, and reshapes it to create a final product.

Compare these to 3D printing or additive manufacturing, which involves adding material in layers to create the final product.

02

Applications

What is additive manufacturing? Though it has been around for decades, additive manufacturing is still a relatively new technology compared to traditional manufacturing. In this guide, we hope to answer some of the most fundamental questions about 3D printing and additive manufacturing and give you all the information you need to begin harnessing the power of this exceptional technology.

03

Advantages of SLS (Selective Laser Sintering) with Strategic Prototyping Solutions Pvt Ltd.

-

Complex Geometry:

SLS can create intricate and complex shapes without needing support structures.

-

Versatile Materials:

SLS can work with a variety of metal powders, including nylon, plastics, and elastomers.

-

High Productivity:

SLS is known for its speed and efficiency in producing functional, durable prototypes and end-use parts.

-

Cost-Effective:

SLS can be a cost-effective alternative to traditional manufacturing methods for low to mid-volume production.

-

Strong and Durable Parts:

SLS creates strong, durable parts with good isotropic properties, meaning their strength and properties are similar in all directions.

04

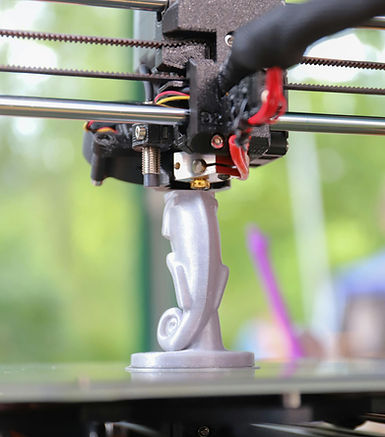

FDM Printing Technology with Strategic Prototyping Solutions Pvt Ltd.

-

Ease of use:

FDM printers are relatively simple to operate and maintain, making them accessible to a wide range of users, including hobbyists and businesses.

-

Material versatility:

FDM supports a wide variety of thermoplastics, including durable engineering-grade materials, high-performance polymers, and composites.

-

Rapid prototyping:

FDM enables quick and efficient prototyping, allowing for rapid iteration and testing of designs.

-

Large build volume:

FDM printers can handle large parts and multiple smaller parts in a single print job, making them suitable for various applications.

-

Reduced material waste:

FDM uses a "bottom-up" approach, minimizing material waste compared to subtractive processes like CNC machining.

-

On-demand manufacturing:

FDM allows for the production of parts on demand, eliminating the need for large inventory and reducing lead times.

-

Environmentally friendly:

FDM can use recycled and recyclable materials, contributing to a more sustainable manufacturing process.

-

Cost-effectiveness:

FDM is generally less expensive, offering a low initial investment and material costs.