Multi Engineering Prototype Manufacturing

Multi-engineering prototype manufacturing refers to the process of creating prototypes

that integrate multiple engineering disciplines, such as mechanical, electrical, software, and materials engineering, to develop functional models or systems. This approach allows teams to design, test, and refine complex products in a collaborative and iterative manner before moving into mass production.

01

Key Features of Multi-Engineering Prototype Manufacturing with Strategic Prototyping Solutions Pvt Ltd.:

1. Interdisciplinary Collaboration: Combines expertise from different engineering fields to develop comprehensive prototypes.

2. Iterative Development: Enables testing and refining designs to improve functionality, usability, and performance.

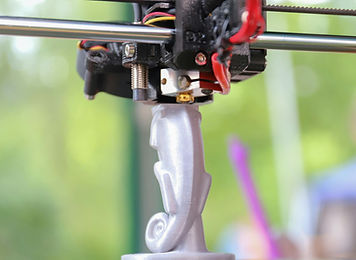

3. Rapid Prototyping Technologies: Utilizes advanced tools like 3D printing, CNC machining, VMC, Sheet Metal Forming, shaping, Pressing, pipe bending, TIG/MIG welding, Laser Cutting and support in simulation software for faster production cycles.

4. Cost-Effectiveness: Helps identify and resolve design flaws early, reducing production costs and risks.

5. Customization and Flexibility: Allows for the creation of tailored solutions for unique product requirements.

02

Applications

- Automotive and Aerospace: Prototyping vehicles, engines, and components that integrate mechanical and electronic systems.

- Medical Devices: Developing functional prototypes of surgical tools, diagnostic devices, or wearable technology.

- Consumer Electronics: Creating prototypes for smartphones, IoT devices, and home appliances.

- Robotics: Producing robots with integrated mechanical, electrical, and software systems.

03

Market Drivers

Rising Demand for Complex Products: Industries such as automotive,

aerospace, and electronics require highly integrated prototypes involving mechanical, electrical, and software components.

Technological Advancements: Innovations in rapid prototyping methods, such as 3D printing, CNC machining, and simulation tools, are driving growth.

Shorter Product Development Cycles: Companies are prioritizing rapid

prototyping to reduce time-to-market for new products.

Increased Focus on Customization: Businesses are looking for tailored

solutions to meet specific customer requirements, boosting demand for multi- disciplinary approaches.

Cost Savings in Development: Early-stage prototyping helps identify design flaws, minimizing production costs and risks.

04

Functional Prototype

Functional prototyping with 3D printing in Strategic Prototyping Solutions Pvt Ltd. involves creating prototypes that not only resemble the final product but also function realistically, allowing for testing and refinement before mass production. This method is faster and more cost-effective than traditional prototyping techniques, enabling designers to iterate quickly and identify issues early on. 3D printing allows for the creation of complex geometries and intricate details, making it suitable for a wide range of applications.